high quality brass Safety valve air compressor safety valve

Our factory are good at machining,sample or drawing will be welcome.

We always try to reduce the cost to increase value for customer.

high quality brass Safety valve air compressor safety valve

Product Description

1、Technical standard

|

|

FOLS VAVLES | ||

|

|

Product name | 207 Brass ball valve | ||

|

|

manufacturer | GUANGZHOU FOLS VALVES | ||

|

|

Materials | Brass body/iron lever/brass core/brass ball | ||

|

|

Applicable temperature | -10℃-- +110 ℃ | ||

|

|

working Pressure | 1.6Mpa | ||

|

|

|

|

|

|

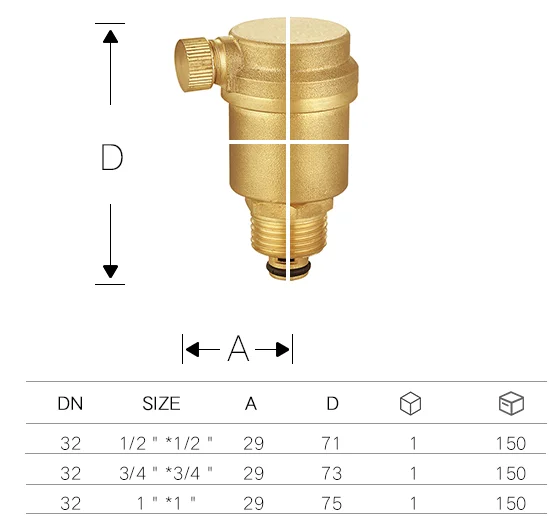

| Product Spec /Size |

|

L | H |

|

| G3/8" |

|

47 | 113 |

|

| G1/2" DN15 |

|

47 | 113 |

|

| G3/4" DN20 |

|

47 | 113 |

|

| G1" DN25 |

|

47 |

113 |

|

Products display

2、Advantage:

-

Safety valve (exhaust valve)

According to the working principle, Safety valves are divided into two types: spring type and lever type. Spring type safety valve depends on spring force, and lever type safety valve depends on gravity work of heavy hammer. According to the structure form, it can be divided into closed and non closed type. Flammable, explosive and toxic media are closed, and the use of air, steam and inert gas is not closed. According to the opening level, it is divided into full start and micro opening. The opening height of the full valve disc is 1/3~1/4 of the seat diameter. The 1/15~1/20. boiler steam system with the height of the opening valve is the diameter of the valve seat.

Function

The use safety valve is an automatic valve. Its function is to ensure that the boiler or other pressure equipment is not damaged by overpressure. When the pressure exceeds the take-off pressure, the valve will automatically open. After removing some gases, the valve will automatically shut down after the pressure is restored.

When the working pressure is more than 0.6MPa, the starting pressure of the use of the safety valve should be 1.05~1.1 times the working pressure; when the working pressure is <0.6MPa, it should be the working pressure of 1.2~1.25 times. The setting of the take-off pressure should not be higher than the allowable pressure of the boiler or equipment, but it should not be set too low, otherwise the inertia will be released to reduce the pressure to too low to affect the normal operation. Because there is a 20% pressure difference between the jump pressure and the back seat pressure, if the pressure is set at the working pressure, the back seat pressure will not be able to meet the requirements of the use. The safety valve used in pairs should take a 0.02~0.05MPa of difference, so as to prevent two valves from taking off at the same time, making the discharge volume too large and wasting energy. The outlet diameter of the safety valve should be 1 larger than the diameter of the inlet pipe (~2), and it should be as reliable as possible. It is damaged by pressure. When the pressure exceeds the take-off pressure, the valve will automatically open. After removing some gases, the valve will automatically shut down after the pressure is restored.

When the working pressure is more than 0.6MPa, the starting pressure of the use of the safety valve should be 1.05~1.1 times the working pressure; when the working pressure is <0.6MPa, it should be the working pressure of 1.2~1.25 times. The setting of the take-off pressure should not be higher than the allowable pressure of the boiler or equipment, but it should not be set too low, otherwise the inertia will be released to reduce the pressure to too low to affect the normal operation. Because there is a 20% pressure difference between the jump pressure and the back seat pressure, if the pressure is set at the working pressure, the back seat pressure will not be able to meet the requirements of the use. The safety valve used in pairs should take a 0.02~0.05MPa of difference, so as to prevent two valves from taking off at the same time, making the discharge volume too large and wasting energy. The outlet diameter of the safety valve should be 1 larger than the diameter of the inlet pipe (~2), and it should be as reliable as possible.

our company

Packaging & Shipping

1. Shrink bag --> 2. Small Box --> 3. Carton --> 4. Strong Plywood Case

Packing Information

|

Product Name |

Valve,Pipe,Pipe fitting,pump |

|

Label |

As per customer's request |

|

Packing method |

CARTON, PLYWOOD PALLET, PLYWOOD CASE |

|

Delivery |

Transport by Sea / Air / Express / Pickup |

|

FAQ |

|---|

Q: Are you trading company or manufacturer ?

A: We are a manufacturer.

Q: How long is your delivery time?

A: Generally it is 2-10 days if the goods are in stock. or it is 20-40 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?